[Thin Film Transistor

Film (TFT)]

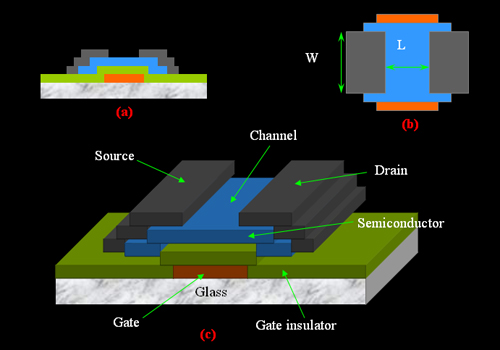

The TFTs in

active-matrix LCD act as simple ON/OFF switches, at different speeds

which depend on the refresh rate of the LCD, for example 60Hz.

Figure 1 shows a simple structure of TFT, it consists of three

terminals: the gate, the source and the drain. As seen in figure 1,

the gate is insulated from the semiconductor film by a gate

insulation film; while the drain and source directly contact the

semiconductor film.

Figure 1. A

simple Thin-Film-Transistor (TFT) structure

In a simple TFT, for example

N-channel TFT, a positive voltage is applied on the gate in order to switch it

ON; the insulation layer can be considered as the dielectric layer in a

capacitor, hence negative charges are induced on the semiconductor channel,

which is the region between source and drain; these negative charges create a

electrons flow from source to drain to make the channel conductive. When a

negative voltage is applied on the gate, electrons are depleted in the channel,

hence almost no current is present. The ON current depends on different

parameters, for example channel width, channel length, gate voltage and the

threshold voltage of the TFT.

When the TFT is switched ON, a

data voltage is applied on the source, the drain with the LC load capacitance

will charge up to the voltage with same amplitude, i.e. transferring the data

voltage from the data line to the pixel electrode. When switched OFF, no current

in the channel, and data voltage cannot be transferred.

The first TFT for LCD was made

of Cd-Se semiconductor thin films, however this is not compatible with normal

process. In spite AMLCD with Cd-Se has a better performance, its

commercialization is still not success.

While a P-channel TFT can be

switched ON by applying a negative voltage on the gate, and can be switched OFF

by a positive voltage on the gate.

TFTs can be formed by three

different silicons, they are: crystalline silicon, poly-silicon and amorphous

silicon; and in practical manufacturing, poly-silicon can also be processed

under low and high temperature, i.e. Low-Temperature Poly-Silicon (LTPS) which

can be built on common low-cost glasses, and High Temperature Poly-Silicon (HTPS)

which needs quartz plate.

Since the crystalline Si owns

higher mobility, it could integrate more peripheral electronics, hence higher

pixel-density-required devices, like projection light valves, usually use

crystalline Si.

Amorphous silicon is widely

used in LCD monitor and TV because of its easy manufacturing on large glass

substrates, but it has a lower mobility; however during manufacturing, the a-Si

is formed by using SiH4, the hydrogen enters into the silicon film, and can

improve the loosen Si-lattice in a-Si, thus enhance its performance. The a-Si

can therefore be also referred as a-Si:H. The normal electron mobility of a-Si:H

is ~0.3-1 cm2/Vsec, compared with c-Si¨s >500 cm2/Vsec, it is quite small. But

for AMLCD¨s TFT¨s switch, it is enough. On the other hand, its hole mobility is

very low, therefore only N-channel TFT can be practically used. Another drawback

of a-Si is its high photoconductivity, which cause the undesirable photo-leakage

current in the OFF state. To avoid it, a cover layer is used to shield it from

ambient and backlight.

Poly-Si can be used to make

both P-channel and N-channel TFTs. Because of its relatively high mobility, both

row and column drivers can be integrated on the glass, even D/A converters,

DC/DC converters and (micro)processors can be integrated too, which

significantly cut the cost from external driver and other devices¨ chips.

However the off current of Poly-Si is much higher than a-Si, i.e. the OFF state

is not stable because of the charge on the pixel capacitor cannot be maintained.

In order to decrease the OFF current, a dual gate structure and a lightly doped

drain (LDD) were proposed. Both methods can effectively lower the OFF current.

Table 1 shows a brief

characteristic comparison among different TFTs, and their corresponding

applications.

|

Switching

devices |

Mobility*

(cm2/Vsec) |

Highest

process temperature |

Major

applications |

|

a-Si TFT |

0.3-1 |

~ 3000C (glass) |

Laptop screen,

PC monitor, LCD TV |

|

High-T poly-Si

TFT |

100-300 |

~ 10000C

(quartz) |

Projection light

valves, viewfinders |

|

Low-T poly-Si

TFT |

10-200 |

~ 5000C (glass) |

PDA and laptop

screens, Projection light valves, viewfinders |

|

Crystalline Si

MOSFET |

400 |

~ 11000C (C-Si) |

Projection light

valves, viewfinders |

|

Thin film

diode |

|

< 3000C (glass) |

Handheld

devices' screen |

Table. 1 different types of switching devices for active matrix LCD.

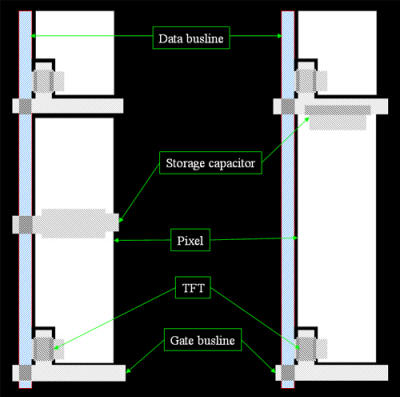

Figure 2 shows a typical pixel

structure of AMLCD. It is worth to note that a storage capacitor is connected in

parallel to pixel capacitor in order to retain the charge at OFF state, and

decrease the voltage dependence and leakage current in the LC capacitance, hence

the control of RMS voltage on the pixel is easier.

Figure 2. A TFT

AMLCD's pixel layout (color-filter substrate is not shown).

Further Readings

and References:

Toshihisa

Tsukada, "TFT/LCD : liquid-crystal displays addressed by thin-film

transistors", Gordon and Breach (1996).

Willem den Boer,

"Active Matrix Liquid Crystal Displays: Fundamentals and Applications", Newnes (2005).