ˇˇ[Polymer Dispersed Liquid

Crystal (PDLC) mode]

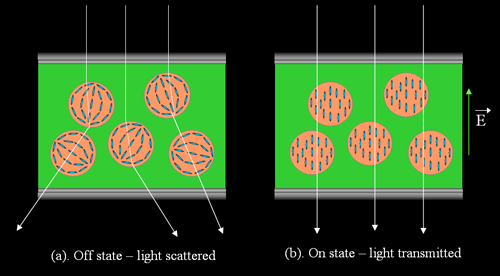

The PDLC display consists of droplets of

liquid crystals inside a polymer network shown in figure 1. These

droplets are sized from 0.3¦Ěm to 3¦Ěm, and inside which the

molecules align themselves in a bipolar configuration.

Figure 1.

Working principle of Polymer Dispersed Liquid Crystal (PDLC) display

In the off state, the droplets are randomly

aligned, the refractive index n' seen by the light will be different

from np, which is the refractive index of the polymer,

hence the light is scattered or reflected in a large angle towards

the viewer. In the on state, the LC molecules orient uniformly along

the direction of the applied field, therefore the no is

the refractive index seen by the light, and usually np is

chosen as np ~ no, for this index matched

situation, light can be transmitted with a very high transmission.

Obviously, the black/off state appears milky opaque, it is a poor

black state, as a result, the contrast ratio of PDLC is relatively

low.

The formation of droplets inside the polymer

can be a micro-encapsulation process (NCAP), or a phase separation

process. In the first process, an aqueous emulsion consisting of

polymer and LC is coated on a substrate then let it dry. The second

process is a polymerization induced phase separation: the mixture is

prepared by homogeneous solution of pre-polymer LC and curing agent /

photo-initiator which catalyzes the polymerization process when the

mixture is UV irradiated. Phase separation can also be thermally

induced or solvent induced.

The working voltage and response time of the

PDLC can be affected by many factors, but mainly the resistive and

dielectric properties of LC inside the droplet and the polymer.

These properties affect the internal electric field of the droplet

which differs from the field outside the droplet. The competition

between these two field determines the final director configuration

inside the droplet, therefore, the work voltage and response time

will be present. Other factors like the size and shape of the

droplets, the viscosity of the LC etc.

There are a few factors influencing the

contrast ratio of the PDLC display. First of all is the cell gap and

the density of the droplets, they are proportional to the contrast

ratio. Secondly it is the temperature. As temperature decreases, no

decreases and ne increases, the birefringence becomes

larger, so is the scattering. As a consequence, the black/off state

is darker, so contrast ratio is higher.

Since no polarizers are not needed, high

brightness is obtained. PDLC can be used into different

applications. For example, as a light valve, PDLC can be made into a

privacy window. PDLC also find applications in project systems.

Further Readings

and References:

Fergason, J. L. "Polymer encapsulated nematic liquid

crystals for display and light control applications". SID Int. Symp.Dig.

Technol. 16, 68¨C70 (1985).

J.W. Doane, N. A. Vaz, B. G.Wu, and S. Zumer, ˇ°Field

controlled light scattering from nematic microdroplets,ˇ± Appl. Phys. Lett.,

Vol. 48, 269 (1986).

J. W. Doane, A.

Golemme, J. L. West, et al, "Polymer Dispersed Liquid Crystals for

Display Applications," Mol Cryst Liq Cryst 165, 511 (1988).

J. L. West, "Phase

Separation of Liquid Crystals in Polymers," Mol Cryst Liq Cryst 157,

427 (1988).

T. Nagata et al.,

"Silicon Chip Based Reflective PDLC Light Valve for Projection

Display", SID Symposium Digest 29, 37

(1998).

ˇˇ